What İs Manufacturing Software?

Production software is software used to plan, manage and monitor the production processes of an enterprise. These software are used to increase the production efficiency of enterprises, reduce costs and meet customer demands. Production software may include various modules and functions to optimize materials management, work order tracking, production planning, productivity analysis, inventory management, and other production processes.

Odoo Manufacturing

Odoo Manufacturing helps manufacturers schedule, plan and process manufacturing orders. With the work center control panel, put tablets on the shop floor to control work orders in real-time and allow workers to trigger maintenance operations, feedback loops, quality issues, etc.

Create a bill of materials

A Bill of Materials (or BoM for short) is a document that defines the quantity of each component required to make or deliver a finished product. It can also include various operations and the individual step guidelines needed to complete a production process.

In Odoo Manufacturing, multiple BoMs can be linked to each product, so that even product variants can have their own tailored BoMs.

Correctly setting up a BoM helps optimize the manufacturing process and save time.

Set up a bill of materials (BoM)

The simplest BoM setup is one without operations or instructions, only components. In this case, the production is solely managed using Manufacturing Orders.

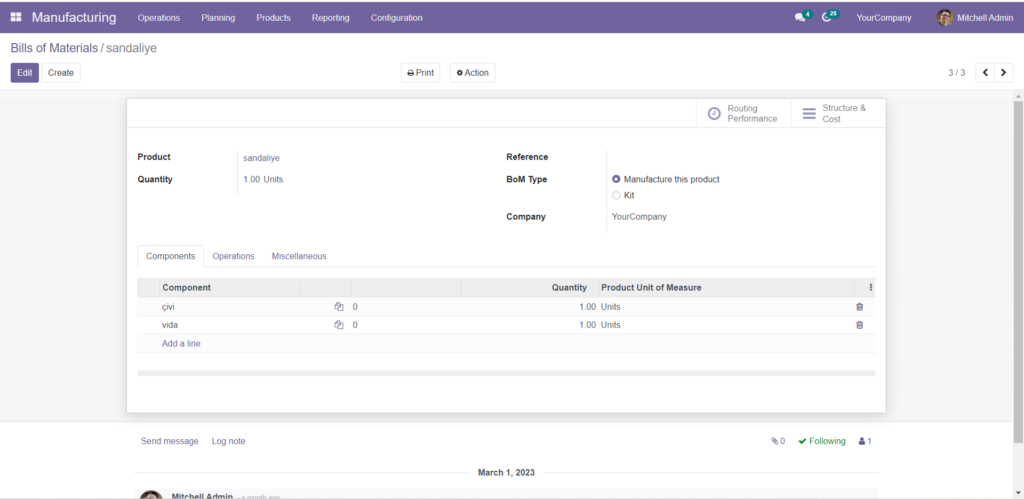

To create a BoM from the Manufacturing module, go to Products ‣ Bills of Materials. Then, click Create. Next, specify the Product.

For a standard BoM, set the BoM Type to Manufacture this Product. Then, click Add a Line to specify the various components that make up the production of the final product and their respective quantities. New components can be created quickly through the BoM, or can be created beforehand in Manufacturing ‣ Products ‣ Products ‣ Create. Finally, click Save to finish creating the BoM

Set up operations

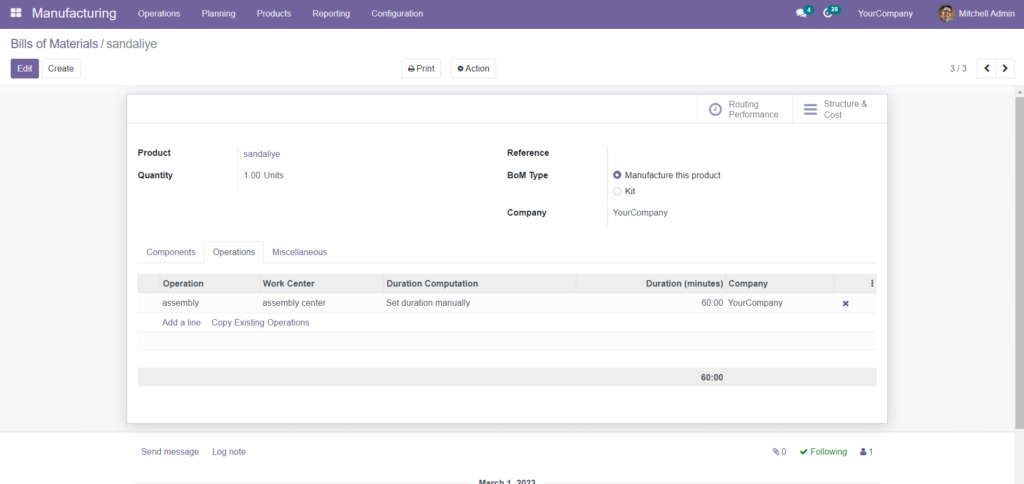

Add an Operation to a BoM to specify instructions for production and register time spent on an operation. To use this feature, first enable the Work Orders feature in Manufacturing ‣ Configuration ‣ Settings ‣ Operations.

Then, when creating a new BoM, click on the Operations tab and click Add a line to add a new operation. In the Create Operations box, give the operation a name, specify the Work Center and duration settings. Like components, Odoo gives the option to specify a product variant in the Apply on Variants field so the operation only applies to that variant. Finally, click Save & Close.

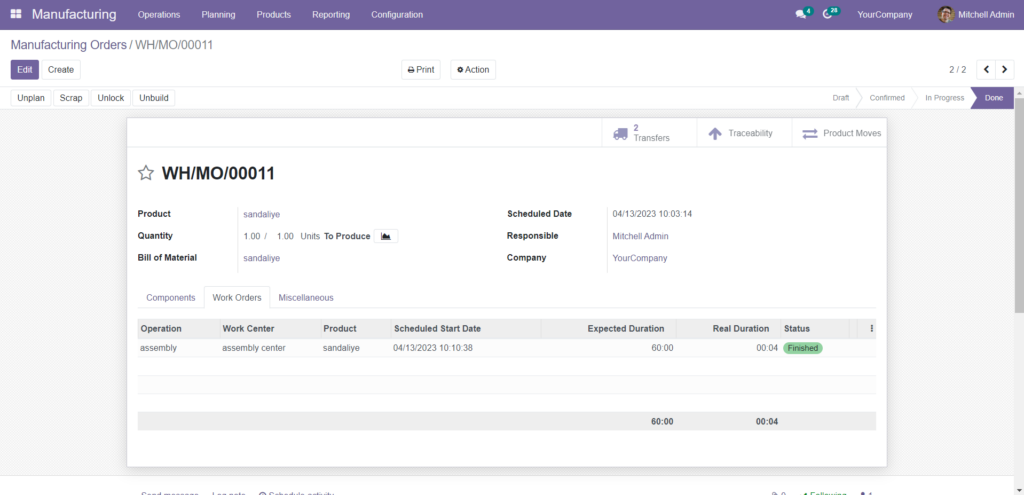

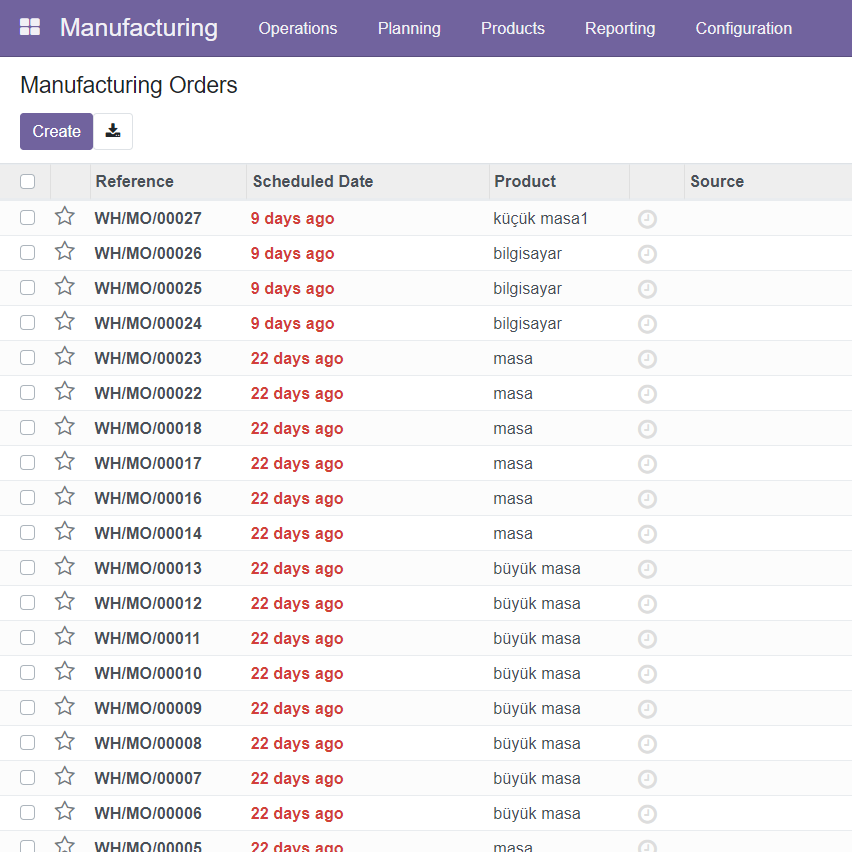

Manufacturing Stage

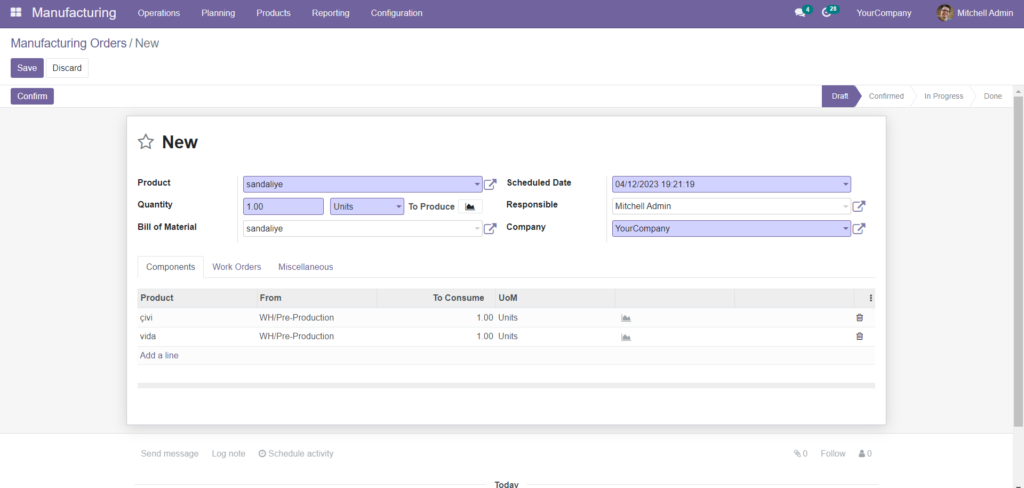

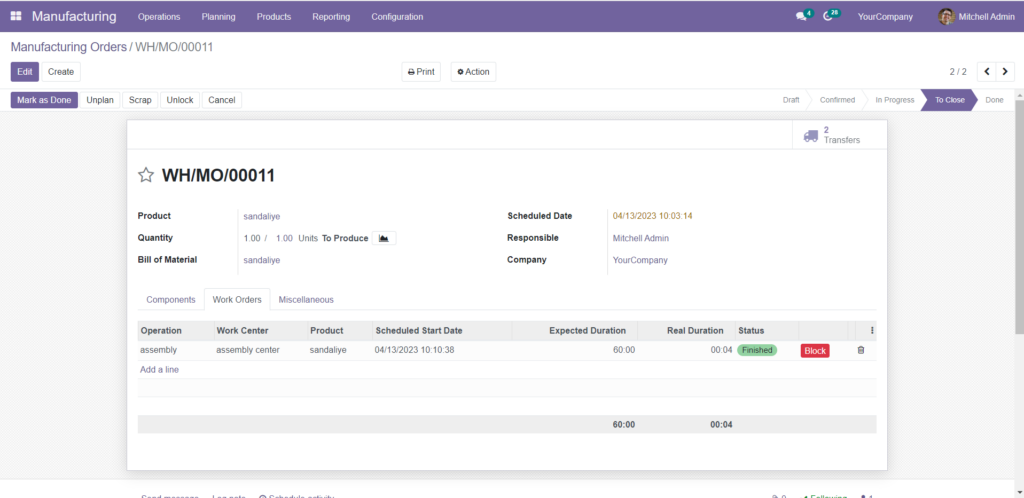

For production go to operations ‣ Manufacturing Order and Create button. Select the product you created in the product section and save it.

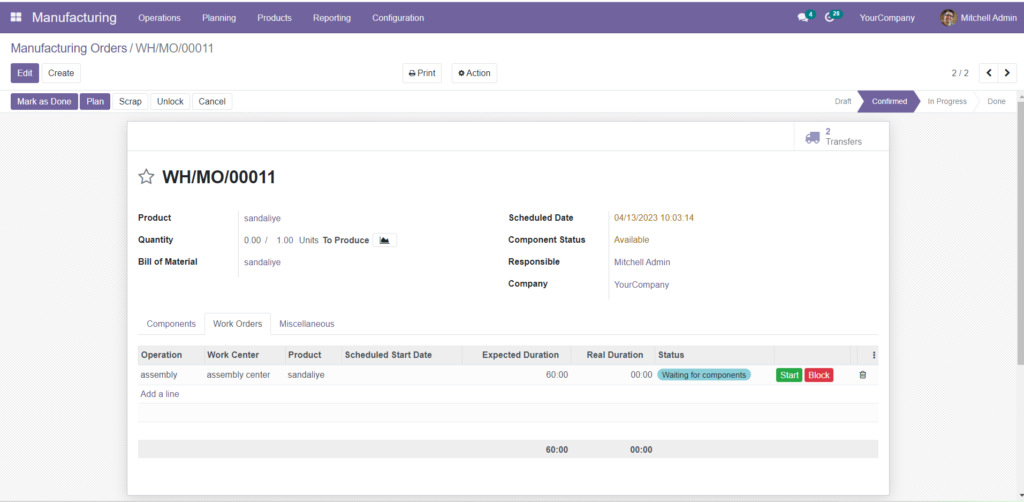

After saving the work order, confirm the work order. Then start your job by going to the work orders option.

Wait for your job to finish after you finish the start process and mark it as the last job finished.

After clicking the mark as done button, your production process will be completed.